A Novel Solution To A Global Problem

While powerplant-style centralized renewable energy will play a major role in the future of our world, decentralized clean energy production (like solar panels on a roof) is growing in popularity and will collectively have a massive contribution. But what about something more dynamic, that can provide decentralized industrial-scale energy regardless of sunlight or wind conditions, and can do it on demand? This is where GenHydro’s technology comes in.

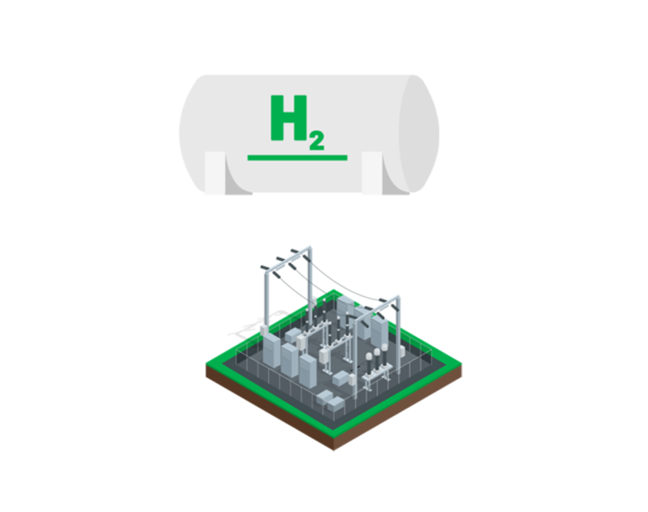

The GenHydro system utilizes waste metals like aluminum, to separate hydrogen from H2O and also cogenerate thermal and electrical energy. This technology means decentralized, scalable, and reliable emissions-free energy that can meet the needs of a variety of users while also growing a network of green hydrogen production.

Extracting energy from waste aluminum

Our novel reactant-based approach produces on-demand green hydrogen that is economically and commercially scalable today

Waste to Hydrogen + Energy

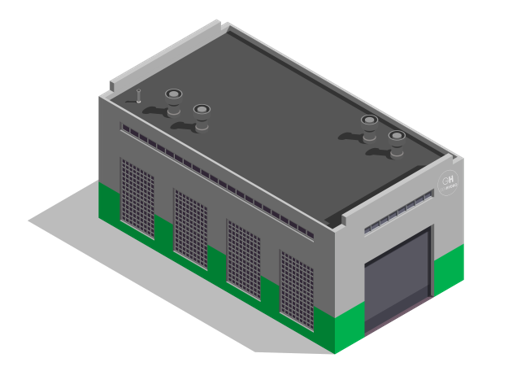

Fundamentally what GenHydro does is waste to hydrogen + energy. We source waste aluminum, process it into our reactant powder (solid fuel), and use this solid fuel in modular GenHydro reactors, placed at a customer’s location, for emissions-free on-site hydrogen production and clean energy generation.

Click Below To Learn More about Each Step

1. Recycled and scrap aluminum

2. GenHydro™ Processing

3. Solid

Fuel

4. renewable hydrogen and energy

Step 1

Aluminum scrap is milled down to micron-sized particles and combined with a chemical promoter that will assist the reaction

Step 2

When exposed to high pressure and high temperature steam, the surface of the aluminum begins to corrode within milliseconds, taking the oxygen from the steam and freeing the hydrogen gas

Step 3

As the steam makes its way through the aluminum particle, hydrogen forms under the surface building pressure until the hydrogen is freed. The oxidized aluminum breaks into smaller particles and releases thermal (heat) energy

Step 4

The reaction is completed with a mix of hydrogen, aluminum oxide, and steam exiting the reactor and going through a series of separation steps. Excess steam is recycled to keep the reaction going