Happy February 7th, one of our favorite days of the year—better known as National Periodic Table Day!

Each year this day is recognized to honor and show appreciation for the critical building elements we owe many discoveries and research in science to!

At GenHydro, the key to our clean hydrogen production approach is a series of elements known as reactive metals. Our primary usage comes from aluminum, but there are a few other metals that are just as or even more reactive than aluminum. The most reactive metals are known as alkali metals, which are never found naturally in metallic form. It is quite difficult to have these alkali metals in metallic form due to their high levels of reactivity.

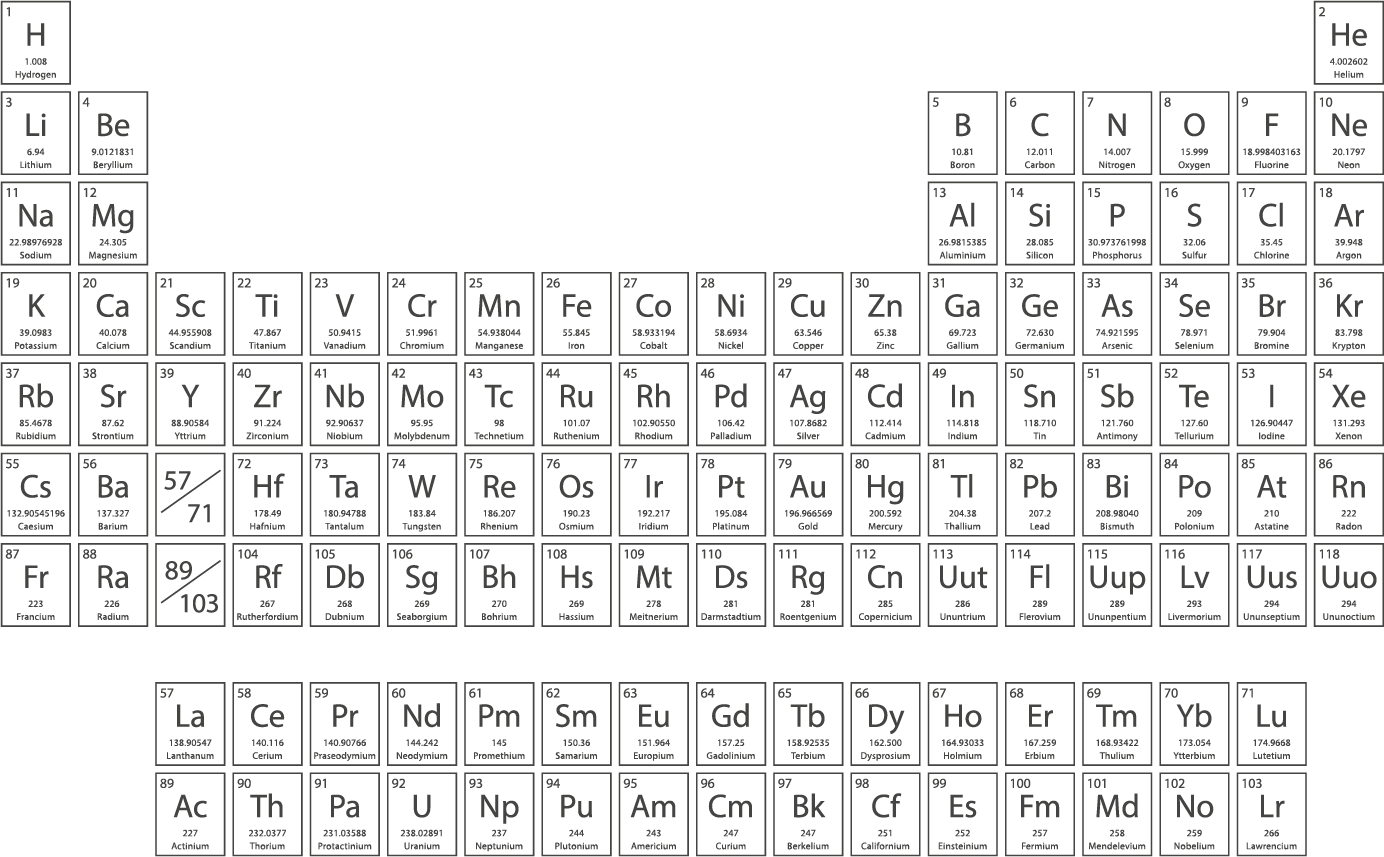

Hover over the highlighted elements below to learn more about reactive metals

Aluminum

Aluminum is found naturally as aluminum hydroxide, predominantly in a type of rock known as bauxite. Once separated from the bauxite rock the aluminum hydroxide is calcined (heated) at very high temperatures to remove the hydroxide ion, leaving high-purity aluminum oxide. The final step to getting aluminum metal is known as "electrolysis," which removes the oxygen leaving behind molten aluminum that is then formed into various shapes and sizes. Once in metallic form, aluminum can be recycled an unlimited number of times, but a lot of aluminum ends up out of this circular stream, and that's the aluminum that GenHydro makes use of for producing hydrogen, electricity, and other products.

Silicon

Silicon is found in nature mostly as silicon oxide. Whether it be sand on the beach or glass, silicon oxide is indispensable to our daily lives. Silicon metal is made from quartz; a rock with a high silicon oxide content. The quartz is placed in a very high-heat furnace in the presence of an anode that helps separate the oxygen from the silicon, leaving behind pure silicon metal.

Magnesium

Magnesium is found in nature in multiple forms, but the primary form used for metal production is magnesium chloride. This is a salt that can be sourced from the ocean and is practically unlimited in its availability. Magnesium is separated from its compound form by means of electrolysis. Magnesium, and some other reactive metals, has some advantages over lithium and is seen as one of the potential alternatives to lithium when it comes to manufacturing rechargeable batteries.

Calcium

Calcium is most commonly found in limestone as calcium carbonate, which can be heated to the point of getting calcium oxide, but this releases the carbon in the form of carbon dioxide. This is primarily used for cement production, which has very high CO2 emissions. Since calcium is highly reactive it is difficult to obtain and keep in a metallic form. Once a metal, calcium will readily react with many chemicals, but especially with oxygen or water, which results in a violent reaction. Calcium is so reactive that even as an oxide it will react with water, which is why water is added to cement, as this causes a crystallization process that gives cement its strong binding capabilities.

Sodium

Sodium is most commonly found in nature as various salts, the most familiar of which is sodium chloride, which is used as table salt. Since sodium is a highly reactive metal it is very difficult to separate sodium from other elements to get pure sodium metal. Once in a metallic state, sodium will easily react with oxygen, water, chlorine, and other elements, returning to some form of salt. Sodium is being explored as a potential alternative to lithium in batteries since it is much more abundant than lithium and easy to source.

Potassium

Potassium is most abundantly found in nature in a mineral salt called "potash," which is also where potassium gets its name. The most common use for potassium is as potassium chloride, a vital ingredient to plant fertilizers. When potassium is isolated from other elements it takes a metallic state, which is highly reactive with oxygen, water, chlorine, and other elements.

Lithium

Lithium is found in nature as lithium carbonate, most commonly in mineral springs where the lithium carbonate can be extracted. Lithium is most commonly known for its use in lithium-ion batteries, which are used for cell phones, laptops, electric vehicles, and more. Since lithium metal is so reactive, it isn't used in its pure state for battery applications, but instead is used as a metal oxide compound such as lithium cobalt oxide. While lithium-ion batteries have been a technology revolution unto themselves, lithium mining can be damaging to the environment, and so methods for mining lithium that are safer are being explored, as well as alternatives to lithium that are more abundant and easier to mine.

Iron

Iron is one of the most ubiquitous metals on earth, and actually makes up the majority of Earth's molten core. In nature, iron is commonly found as various forms of iron oxide, the most common being hematite and magnetite. As a primary ingredient for steel, iron is mined in billions of tons every year. The reactivity of iron is commonly witnessed on items made from carbon steel that has started to rust, as iron readily reacts with oxygen or water. "Rust" is a common term used to describe iron oxide.

How do reactive metals help us generate emission-free hydrogen?

Generating hydrogen from water through a reaction with aluminum is well-known science that has been practiced as far back as 2008 with the US-DOE. GenHydro has designed, refined and patented a highly cost-effective modality of harnessing this chemical reaction from waste aluminum materials. This process starts with oxygen, the most abundant element on earth, that is also a highly reactive element. When oxygen and reactive metals are combined, they form a practically inseparable bond. The compounds formed by these bonds are known as “oxides.” However, most metals when bonded with oxygen, will not fully form an oxide but will instead create an oxide layer on the surface of the metal that can potentially grow to overtake the entire metal. The process to clean hydrogen and energy continues with bonded hydrogen and oxygen (H2O). Reactive metals actually take the oxygen from water molecules and leave H2 (hydrogen gas) behind. To release the hydrogen, water needs a way to get beneath the oxidized surface of the metal and reach the metal that has not yet oxidized, that will take the oxygen from the water, and set the hydrogen free. The oxidized layer on the metal’s surface is not as easy to get around as it may seem, it requires energy and a chemical assist.

How does GenHydro’s reactor system technology work?

Step 1: Aluminum scrap is milled down to micron sized particles and combined with a chemical promoter that will help assist the reaction

Step 2: When exposed to high pressure and high temperature steam, the surface of the aluminum begins to corrode in milliseconds, freeing the hydrogen gas

Step 3: As the steam makes its way through external cracks in the aluminum, hydrogen bubbles begin to form under the surface. As this pressure builds and the hydrogen is freed, the now oxidized aluminum is broken into submicron particles and release high levels of thermal energy

Step 4: With a mix of hydrogen, aluminum oxide and excess steam leaving the reactor, the reaction is complete! The excess steam is then recycled to keep the reaction going without any need for additional energy input

With thanks to aluminum, the reactive metal essential to our approach, GenHydro is able to efficiently produce three renewable products: renewable energy, clean hydrogen, and alumina (aluminum oxide). GenHydro is shaping a global market for circular decarbonization by providing impactful zero-carbon energy solutions for a cleaner tomorrow.

For more information about GenHydro and to learn more about our technology capabilities and investor opportunities please Contact Us.