Distributed Energy Reimagined.

Hydrogen. Heat. Electricity.

All from one technology.

On-site, renewable energy power plants that run on scrap aluminum.

The first of its kind. A micro-power plant that produces non-stop renewable hydrogen in addition to electrical and thermal energy generation. We’re bringing emissions-free energy independence to the industries that need it most.

A breakthrough in decentralized renewable hydrogen and energy.

How it works.

Step 1

Aluminum scrap is processed and readied for the GenHydro reactor.

Step 2

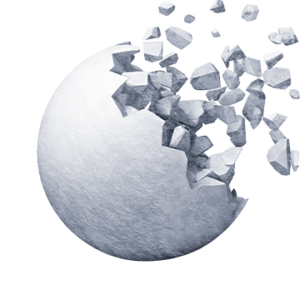

Once in the reactor, the aluminum takes the oxygen from H2O, beginning to free the hydrogen gas.

Step 3

As the reaction continues, the aluminum breaks down into microscopic aluminum oxide particles

Step 4

Fully reacted aluminum results in an output of hydrogen gas, high-temperature steam, and very fine aluminum oxide

From chemistry to commercial.

How we have come closer than ever to deploying a game-changing technology.

Commercial Production Targets.

GenHydro’s first deployed systems will have a production capacity able to meet the needs of many manufacturers and industrial users.

Production Capacity Per Reactor System

A One of A Kind Technology

We believe the reactor system developed by GenHydro is the most advanced of its kind, capable of delivering more than the competition. We plan to commission our first on-site commercial systems in late 2024 and have projects in the development phase into 2025 and beyond.

A One of A Kind Team

The leadership and engineering team at GenHydro is truly one of a kind. Our engineering team has extensive experience in industry, academic, and research environments, meaning they have the know-how to develop, engineer, and build the GenHydro system to meet our client’s needs in the most effective and efficient way possible.

News and articles

The reality of a renewable energy future has for some time exited the realm of debate into the category of fact. The future will run on renewable energy. The only remaining debates are regarding how long until we get there, how we fund it, and what the mix of renewable technologies will be. Keep Reading…

The Biden-Harris administration recently unveiled an unprecedented clean hydrogen strategy, taking a significant step towards a greener future. Learn about the objectives and the revolutionary impact intended by the U.S. National Clean Hydrogen Strategy and Roadmap. Keep Reading…

E-Fuels, also known as “electro-fuels” or “synthetic fuels” are produced from renewable energy sources or electricity that has been decarbonized. Learn about the different types of E-fuels, how they’re produced, and why they’re important in the fight against climate change. Keep Reading…